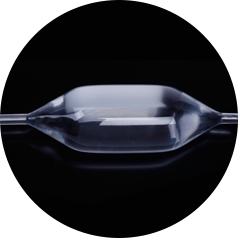

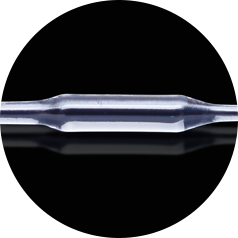

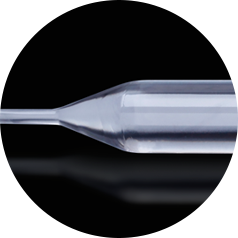

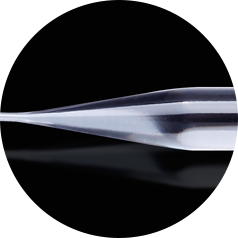

Balloon Process

We have an ISO 13485 qualified Class 7 10,000 clean room with a balloon production output of 30,000/month. Catheter assembly includes a full chain of processes including laser welding, tube stretching, balloon folding (2-8 flaps), positive and negative pressure testing, development ring spin forging, hydrophilic coating, and development ring spin forging.

Classification:

Balloon Technology

Product Details

Balloon Realization Capability

| Diameter |

Iength |

Wall Thickness | Type of Balloon Compliance | Balloon Ends | Materials |

| 0.6~26mm | 5~300mm | Minimum bilateral wall thickness 0.0003 inch; reinforced balloons with special surface configurations available | Noncompliant, Controlled Compliance, Semi-Compliant, Compliant and Super-Compliant | Ends:Conical sharp corner, Conical radium corner and any specified shape. | Nylon and Pebax |

*Balloons with customer-specific performance requirements

Pre

Related Products

Welcome your message consultation

Our staff will contact you within 24 hours (working days).